| Material | Weißblech grundieren |

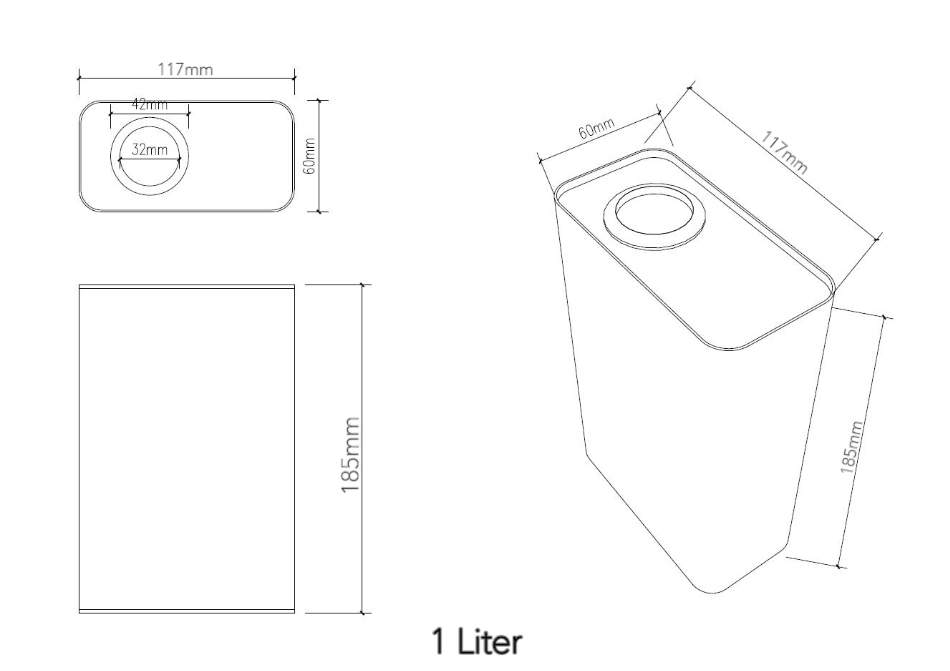

| Kapazität | 1 Liter |

| Dicke (mm) | 0.23~0.28mm or According to customers' requirements |

| Größe (mm) | 117 (L) x 60 (W) x 185(H) mm or make a new mold |

| Draußen | CMYK-Druck |

| Innerhalb | Lacquered with 100% Phenolic epoxy resin, plastic film laminating/plastic film |

| MOQ | 12000pcs for inner coating / external customized printing |

| Zertifikat | MSDS, ISO 9001, UN genehmigt |

| Stichprobe | 2 Stück sind kostenlos, nur das Porto bezahlen |

| Anpassung | 1) probe kann für uns zu kopieren 2) Layout oder 3D-Zeichnung der Blechdose oder des Designs 3) die Größe der Blechdose |

| Zahlung | 30 % T/T-Anzahlung im Voraus und 70 % vor dem Versand oder nach ausgehandelter Methode |

| Lead Time | About 25 days |

| Verladehafen | Shanghai / Ningbo |

1.Wir können die HÖHE an die Kapazität des Kunden anpassen, ohne eine neue Form herzustellen.

2. Design: As per customers' drawings, plain white / metal silver / CMYK printing

3. There are many options for the two accessories: the handle and cap. Usually, there are 3 types of the caps, including Japan style metal squeeze cap with plastic spout, Metal screw cap with iron seal and Plastic telescopic spout cap. There is always one for you!

4. Verpackung: Kartonverpackung / mit Schrumpffolie verpackt und dann mit Riemen auf den Paletten befestigt / nach Kundenwunsch.

Base Material: tinned cold-rolled steel plate

1. Material code: usually SPTE (Steel Plate Tin Electrolytic) or tinned plate that complies with JIS G 3303, ASTM A623 and other standards.

2. Thickness range: 0.18mm - 0.50mm (common range, depending on the tank size, capacity and strength requirements). The tinplate thickness generally used by DS Packaging is as follows:

- 0.37L, 0.8L, 1L, Half Gallon, 2L, 2.5L, 1 Gallon, 4L, 5L cans use 0.23mm, 0.25mm, 0.28mm

- 10L~15L cans may use 0.28mm, 0.32mm, 0.35mm

- 18L, 5 gallon, 20L, 23L steel pail will use 0.32mm, 0.35mm, 0.38mm, 0.40mm, 0.42mm, 0.45mm, 0.5mm

3. Tin plating amount: usually use 2.8/2.8 (tin plating amount on both sides is 2.8g/m²) or similar levels (such as E2.0/E2.0, E5.6/E5.6, according to customer requirements). For food grade or high corrosion resistance requirements, a higher tin plating amount will be selected.

4. Surface treatment:

- Bright: standard glossiness.

- Matte: matte, no glossiness.

- Stone: specific texture, conducive to paint adhesion or reduce reflection.

5. Tempering degree: such as T-2.5, T-3, T-4CA, etc., representing the hardness/toughness of the steel plate. F-style cans often use T-2.5 or T-3 to balance formability and strength.

Description of Can body, Bottom, Top Cover and Accessories

1. Can body:

- Material: mostly tinplate or tinplate.

- Coating: optional inner coating or Clear Lacquer

2. Upper cover and lower bottom: the same raw material SPTE as the can body. DS Packaging generally uses tinplate that is slightly thicker than the can body. Actual production has proved that such a crimping combination will be more solid.

3. Liner/sealing gasket of the lid:

- Material: commonly used PE/PET composite gasket, can also be non-woven gasket, paper gasket with a waterproof film, if the customer has a need, can also customize the most expensive silicone gasket with the best sealing degree.

- Function: provide elastic sealing between the lid and the can mouth to ensure sealing.

4. Handle:

- Material: DS Packaging usually provides two materials: plastic or tinplate. Among them, there are 3 commonly used tinplate metal handles, including European high handles, Japanese wide handles, and iron wire foldable handles.

- Surface treatment: coating (such as epoxy) or laminating may be added to improve corrosion and rust resistance.

Before making a quotation, we need to confirm:

① First, what's your the specific size? Or you can send us the pictures directly.

② Is it filled with liquid or solid? Water-base or solvent-base?

③ Are there any accessories requirements? Generally, accessories include caps and handles.

④ Does the appearance require customized printing (your LOGO)?

⑤ How many do you want?

After confirming the packaging solution, prototype can be made by manually.

① If there is stock tin cans, samples are free, customers only need to pay the shipping fee. We will ship them out in 3 days.

② If you wanna the cans with your LOGO, customer needs to pay the film printing plate fee and proofing fee.

③ The lead time for mold/color printing proofing is about 30 days.